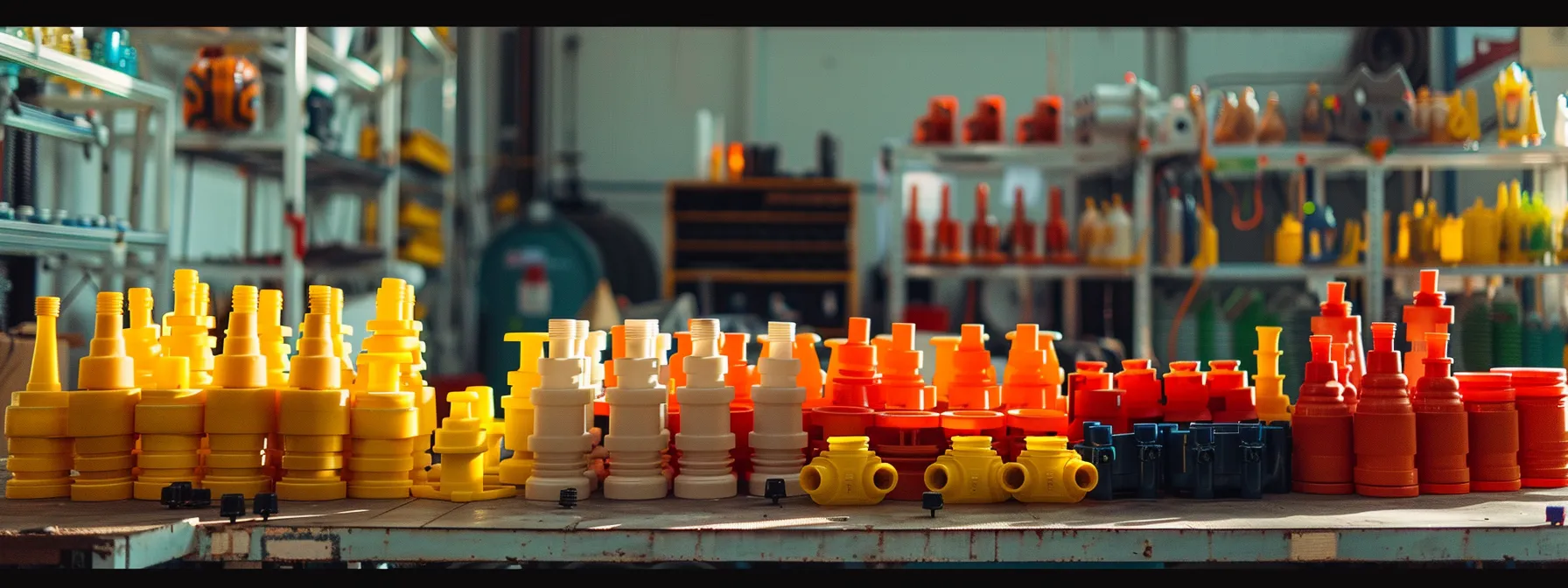

The Importance of Using Plastic Caps and Plugs in Industrial Applications

In the bustling world of industrial operations, the small details often make a significant difference in ensuring safety, maintaining equipment integrity, and enhancing efficiency. Plastic caps and plugs play a critical, yet sometimes understated, role in protecting components during manufacturing, storage, and transport. They are invaluable for preventing contamination, damage, and accidents in various industrial settings. This article delves into the benefits and crucial aspects of using these plastic protection elements in your operations. Keep reading to understand why adopting the right caps and plugs is essential for your business’s success.

Ensuring the Integrity of Equipment with Plastic Protection Components

Preserving the integrity of industrial equipment is an area where plastic caps and plugs shine. They provide a physical barrier against environmental elements that can erode or damage components, such as dust, humidity, and various pollutants.

During manufacturing processes, machinery parts are particularly susceptible to damage. By utilizing caps and plugs, companies protect these parts from impact and abrasion, thereby reducing the likelihood of defects and extending the lifespan of their equipment.

The protection offered by plastic caps and plugs also plays a vital role in storing and transporting industrial components. These small but effective measures prevent the ingress of contaminants that could compromise the functionality and reliability of equipment during later stages of use.

Maintaining a contamination-free environment is crucial for industries that rely on hydraulics, pneumatics, or fluid systems. Plastic plugs and caps are essential in ensuring the purity of these systems, protecting against the intrusion of unwanted substances that could result in blockages or system failures.

The Environmental Impact of Using Plastic Caps and Plugs

Plastic products are often scrutinized for their environmental footprint, and it is important to consider sustainability when using plastic caps and plugs. These components can be eco-friendly when manufacturers focus on producing them from recyclable materials and design them for long-term use or multiple applications.

Industries must manage waste effectively. Companies can significantly reduce their environmental impact using reusable and recyclable plastic caps and plugs. Initiatives to recycle these components after use can greatly diminish the amount of plastic entering landfills.

Innovation in material science has led to the development of biodegradable plastic solutions. These caps and plugs offer similar levels of protection as traditional plastics, while providing a more environmentally friendly end-of-life option. They decompose under certain conditions, lessening their ecological impact.

Manufacturers are also adopting more efficient production methods to minimize the environmental cost of producing plastic caps and plugs. These actions reflect a growing commitment within the industry to balance functionality with ecological responsibility. Caps and plugs represent a utility and a commitment to an evolving industry standard for sustainability.

Innovations in Plastic Cap and Plug Design for Industrial Efficiency

Technological advancements have ushered in a new era of efficiency in designing and using plastic caps and plugs. Engineers are now creating tailor-made solutions to meet specific industry needs, enhancing the functionality of these components while reducing material wastage.

The development of ergonomic designs makes installing and removing caps and plugs faster and less labor-intensive. This improvement leads to time savings in maintenance and assembly processes, directly boosting productivity and reducing labor costs.

Thermal and chemical resistant varieties of caps and plugs have emerged, capable of withstanding extreme environments without compromising their integrity. This innovation allows their use in broader industries, from aerospace to petrochemical operations.

Smart designs incorporate features like venting abilities to prevent pressure buildup or easy-grip surfaces for quick application. Innovations like these have fine-tuned the functionality of plastic caps and plugs, ensuring they fulfill their roles more proficiently and with greater adaptability to complex industrial demands.

Altogether, plastic caps and plugs are indispensable in maintaining equipment integrity, preventing contamination, and improving operational efficiency across industries. Their evolving designs and sustainable production practices highlight their essential role in supporting performance and environmental responsibility.